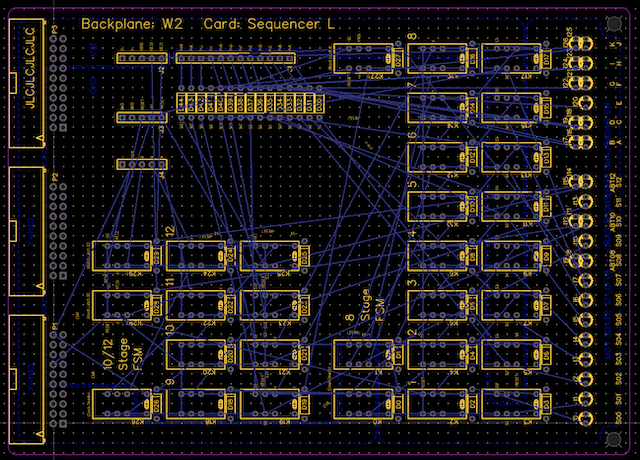

I’ve got the designs for the 24-cycle FSM and pulse distribution in place so all that’s left for the sequencer is to bring the schematics together and then design the PCBs … and yup, that’s PCBs plural as this is going to be another part of the computer that is complicated enough to need spreading over two interconnected cards. The way I can tell this is a ’two card job’ is purely down to the number of relays I’ve used. In this case the total comes to 60 and if you’re really packing them in (6 rows of 8 relays) you can just about get away with a maximum of 48 per card.

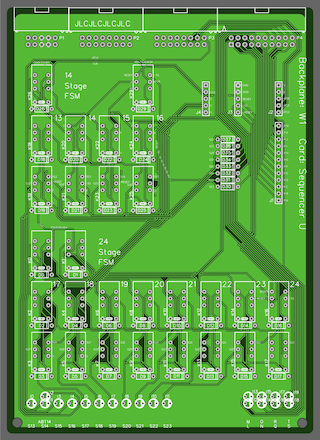

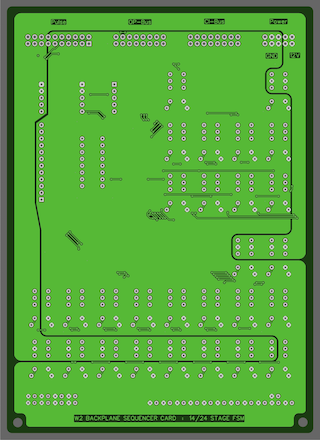

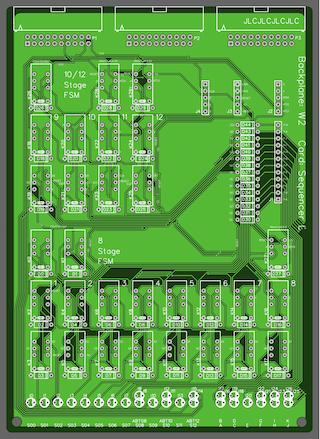

So, two cards it is. The other choice is deciding where to split the design (i.e. what goes on the ‘upper’ card and what on the ’lower’). In this case it seems sensible to place the 8, 10 and 12 cycles plus derived pulses on the lower card and then the remaining 14 and 24 cycles on the upper card. The other consideration is fitting the status LEDs on the front of the cards (and splitting this way fits nicely) and then what signals need to pass between upper and lower cards.

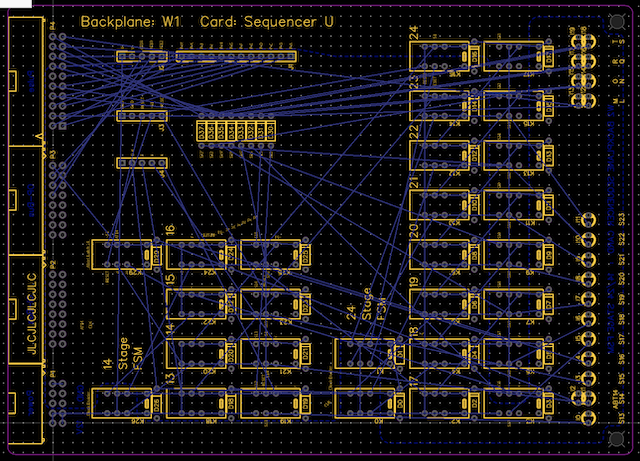

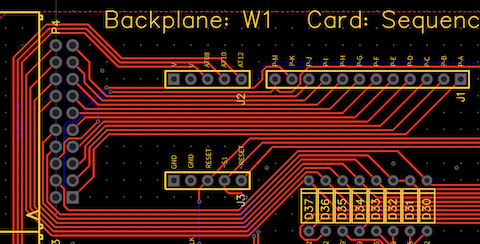

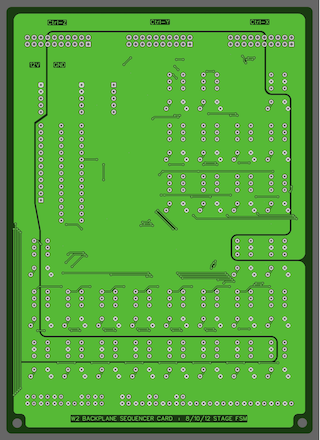

Given I’ve already introduced the FSM and pulse distribution schematics in my last posts I’ll cut straight to the chase and you can find the consolidated upper sequencer schematic here and the lower sequencer schematic here (both in PDF format). In both cases the card is largely defined by the backplane connectors it uses … W1 for the upper card (made up of address, operation and pulse busses) and W2 for the lower card (made up of Control X, Y and Z busses). This is similar to the existing pair of controller cards which also talk to enough of the computer to need access to all the busses offered by the W1 and W2 type connectors.

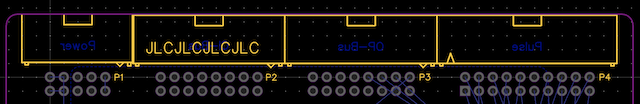

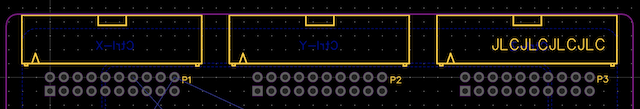

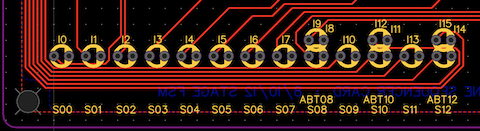

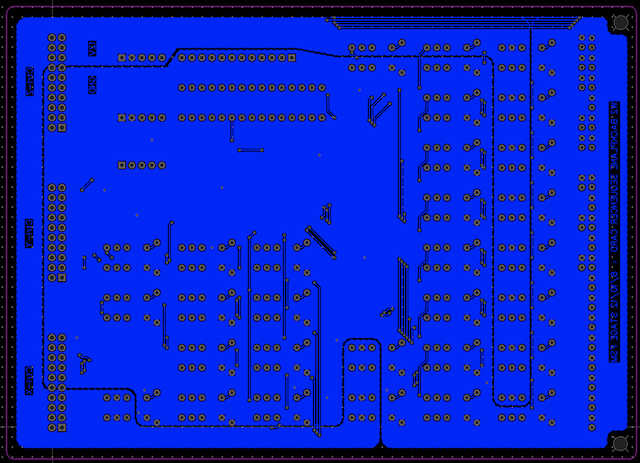

For the PCB design we follow the same basic steps as before for the Y backplane register: place components that have to be in a certain location first; place other components in rough logical groups; lay tracks; build ground/power planes; add text labels etc. In this case we’ll also need to pass additional signals between the cards via an ‘interconnect’. Let’s start then with the backplane connectors as these pre-exist on the W backplane and have to be in a certain location:

Note that the ‘JLCJLCJLCJLC’ text in the top right corner is to let my PCB manufacture know where I’d like them to put their identification code so they can find my PCB amongst all the others they’ll be making. If I don’t specify the location then the manufacturer decides for me and invariably puts it somewhere annoying. In this case I want it underneath a socket so they can see it but I wont. Next up is the LEDs:

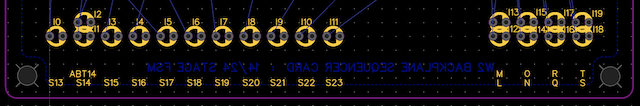

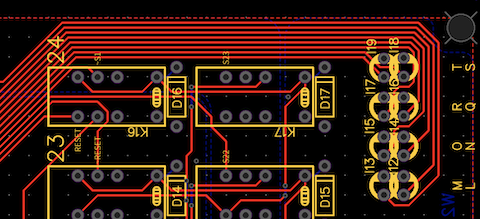

Although it’s not specified on the schematic or the PCB I’ll stick with my usual convention for LED colours and use green for the pulses (representing a ‘result’ output of the card), yellow for the abort signals (representing command/control inputs to the card) and red for everything else (the FSM stages in this case).

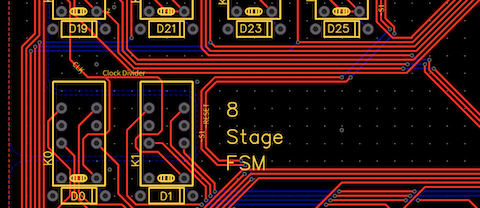

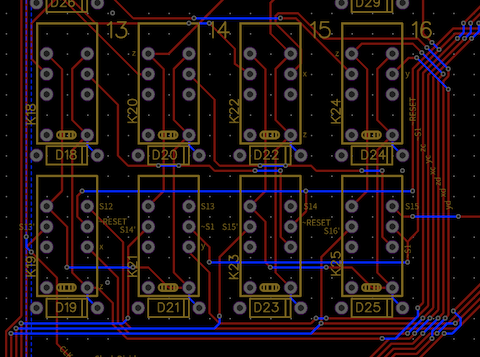

I now need to place the relays, diodes and card interconnects. This often involves just moving things around until there’s a nice fit and the ratlines (showing the connections needed between components) are looking reasonably tidy.

I’ve also labeled the card now I’ve put everything in position. I find this just helps a little when moving on to the most time consuming part of PCB design … laying down the tracks. A good place to start is routing groups of related signals that are heading in the same direction - busses are good examples of this:

It’s then just a case of laying down tracks between groups of relays and any other remaining signals. Another rule I tend to follow is to try and keep the tracks on the front of the card going vertical and then route horizontally on the rear of the card:

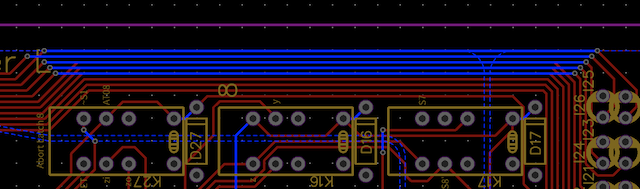

Another good use of laying tracks on the rear of the card is if you’re squeezed for space on the front:

… this tends to work best when near the edge of the card so that it leaves plenty of space for the copper pours. The pours create a large area of copper that fills any space not used up by tracks. This also gives me somewhere to route the ground lines (which come off pretty much every active component) and also the power lines. It’s quite common to have a power plane on one side of the board and a ground on the other but I tend to have ground on both sides (to ensure ground can get around any areas where there’s a lot of tracks) and then route a ‘power river’ through the rear ground plane:

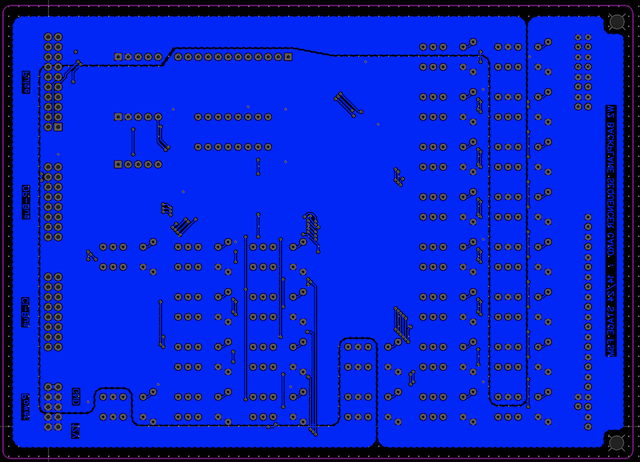

All that’s left then is just to have a good close up inspection of the board to make sure everything is placed well and tracks are routed properly. There’s several built-in tools that help with this such as the DRC which’ll check that pad sizes, track widths, spaces between items and so on are within the abilities of your chosen manufacturer. In my case I’m well outside of those minimum tolerances. Another good idea is to produce a ‘realistic’ image of the final board design to have a last visual check:

If you’d like to take a closer look at any of these you can find the full colour previews in PDF format here for the upper card and here for the lower card. There’s also another version here for the upper card and here for the lower card which seperates the layers out.

That’s the sequencer design fully complete so all that’s left is to send it off to the manufacturer and wait for the PCBs to arrive in the post … once they arrive it’s soldering time.